Digitalization in OIL

OIL had started its digital journey in the year 2019 to imbibe best of Industry 4.0 technologies and put them in use for enhanced operational efficiency for the company. Accordingly project DRIVE (Digital Readiness for Innovation & Value in E&P) was initiated. The primary focus of project DRIVE was on addressing the critical pain areas of OIL, like optimizing gas lift, ensuring real-time status monitoring of wells, analytics and AI in possible functional domains, project management issues like time overrun and effective asset management using IoT, predictive maintenance etc. A total of 11 digital initiatives were taken up under project DRIVE as highlighted below

OIL implemented 11 innovative digital technologies

As of now, 9 out of these 11 digital initiatives are operational and 2 remaining projects are likely to go-live shortly. The success of DRIVE initiatives with visible value addition testifies company’s visionary digital aspiration fortifying foundation of OIL’s Digital journey.

Currently, a multifunctional team is working on next phase of OIL’s digital initiatives under the project DRIVE 2.0. A major focus of DRIVE 2.0 is to set up an integrated Command and Control centre for OIL encompassing all OT and IT infrastructures of OIL.

Real Time Production Monitoring & Analytics

- 140 Field instruments to be deployed for Eastern asset (Hapjan OCS (Oil Collection Station))

- PDMS, network model setup and online simulation s/w to be commissioned for real time and predictive process monitoring

- Faster surface flow line issue detection, reduced production losses, and accurate hydrocarbon allocation through analytics dashboard

Connected Worker

- Digitization of the field operations processes, parameters & operating ranges using industry leading s/w solution.

- Real time data sync b/w s/w solution and Data Management System for improved access to data

- Efficient data collection process with improved operator management opportunities.

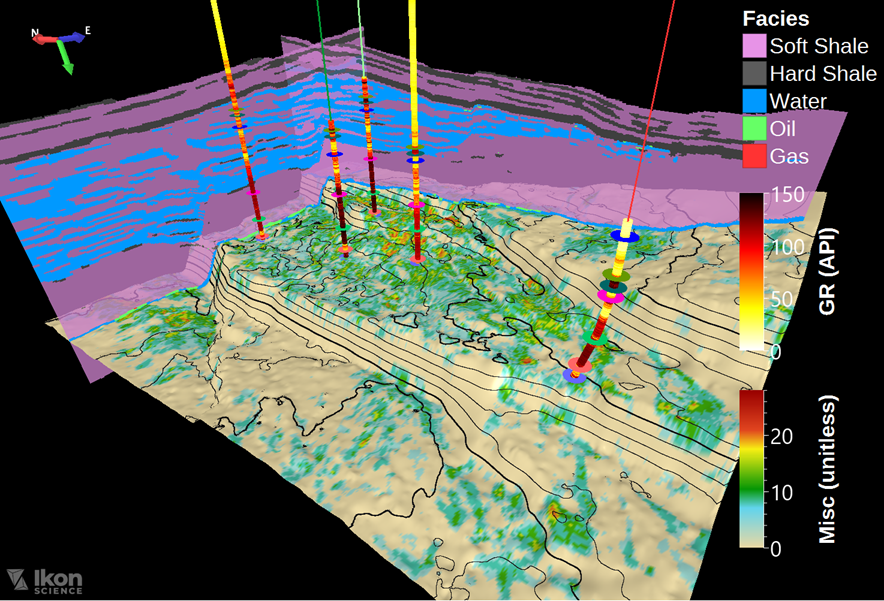

AI Based Reservoir Modeling

- AI based “Big Data” solution (Machine Learning and Data Mining) to develop full field reservoir models based on measurements (facts) offering speed of decision making, optimization avenues and process automation.

- Prediction of future performance of existing producers under various scenarios (eg: change of production bottom-hole- pressure, etc.)

CXO Dashboard

CxO Dashboard is a Business Intelligence (BI) Tool comprising a comprehensive web-based and mobile based dashboard that can analyze and provide insights from data which can help the senior officials and competent authority to make data-driven decisions and work more effectively and efficiently. Key objectives of the solution are as follows:

- End to end integrated view of functional key metrics.

- Correlation of right metrics and data sources to present “Single version of truth” across levels.

- Real time update, alerts, and notifications

- Impactful visualization to generate strategic insights for business leadership.

- Automation of standard reports being currently generated by functions.

- Generation of ad-hoc reports by users as per requirement

- Multi-stakeholder L1-L4 KPI dashboard with advanced UI/UX using industry leading BI Tool and Cloud based architecture.

Enhanced - Real Time Monitoring & Control Center for Drilling

- Central command center (RTOC) set-up at FHQ

- Sensor & real-time connectivity set up between rig sites and command center for CH rigs.

- Drilling analytics software & visualization dashboard setup leading to faster anomaly detection, NPT reduction, and enhanced drilling performance

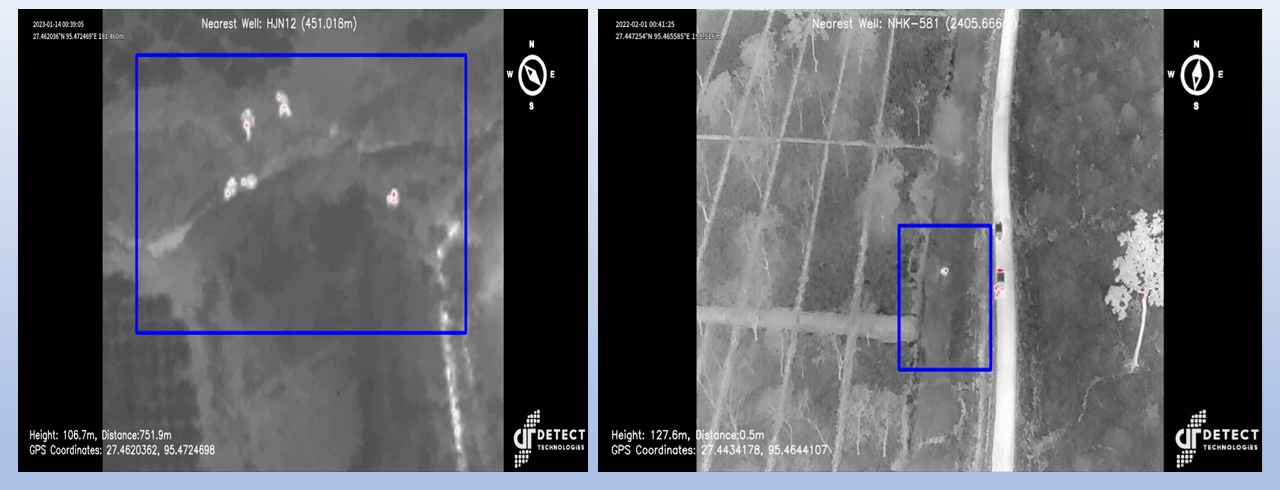

Drone Surveillance for Miscreant Activity

- Video stream-based analytics for encroachment identification, land elevation, miscreant activity, and safety/security.

- Drone based asset surveillance and response plan through 3 teams to be deployed in eastern and central asset.

- Faster and periodic assessment of pipeline RoW to assess developments and threats in proactive manner.

Digital Well Planning Platform

- Digitization of the current depth data drilling program process (involving G&R, chemical, drilling, departments)

- Integration with other E&P applications for a coherent drilling program on a shared platform

- Ability to run sensitivity analysis & NPT analysis for multiple design parameters.

HSSE Management

- HSSE event / incident management platform for reporting near miss, injuries, fatalities etc.

- Display HSE dashboard, generate reports, push notifications for improved KPI monitoring and analytics.

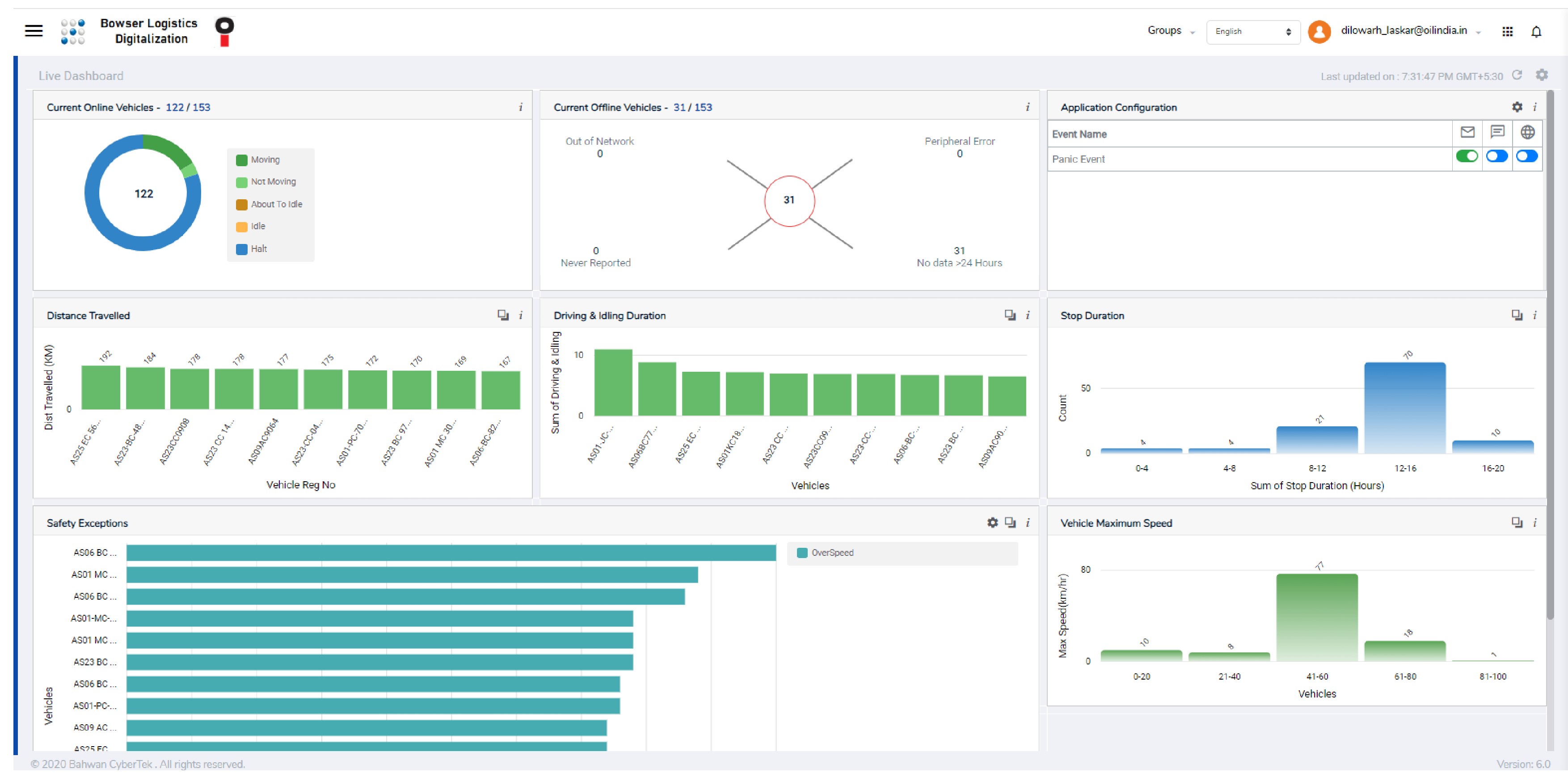

Bowser Logistics Digitalization

- Digitization of planning, vehicle allocation, tracking and data entry processes across Assam assets.

- Leveraging IoT and mobility solutions to streamline the bowser management process both on and off field.

Targeted benefits of cost-of-service reduction through asset optimization and productivity improvement.

Invoice to Pay Automation

- Development of unified vendor portal for submission and tracking of invoices.

- Automation of invoice management process through commissioning of VIM s/w solution.

- Targeted benefits of faster invoice processing, improved productivity of AP team and higher vendor satisfaction.

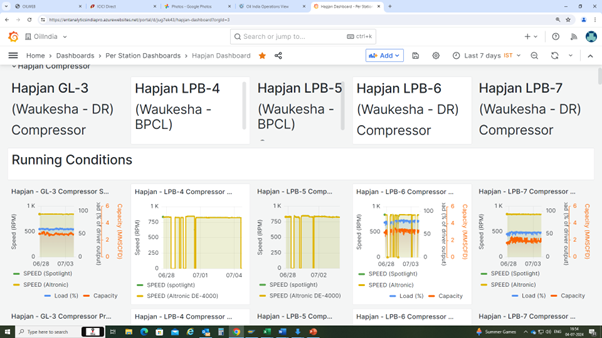

Condition Based Monitoring

- Condition Monitoring Solution for Gas Compressor packages to help engineers and maintenance personnel to do performance monitoring and predictive maintenance of its Gas Engine driven Reciprocating Gas Compressor packages deployed in the region of Assam

Real Time Production Monitoring & Analytics

- Realtime condition monitoring of asset performance parameter for anomaly detection (e.g., vibration, temperature, pressure etc.)

- Maintenance trigger based on bad actor assessment leading to optimal maintenance costs, spares spend and asset downtime.